Zhixiangyuan Transformer Machine Production Line -EE10 Winding

Email:rhea@zxycoil.com/kath@zxycoil.com

WhatsApp:13554723725/13380695029

We are a comprehensive research and development manufacturer specializing in the production of inductors, coils, audio isolation transformers, and power transformers. We have two factories and a team of engineers who can produce transformers according to your requirements and drawings. And quickly produce samples.

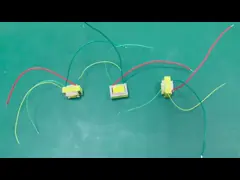

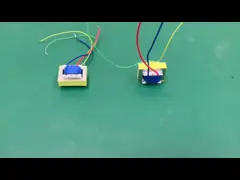

The winding of EE10 transformer starts with carefully selecting the appropriate winding wire diameter, which is determined based on the design requirements such as voltage and current of the transformer. When winding, professional winding equipment is usually used to tightly and evenly wrap the winding wire around the EE10 magnetic core skeleton. First, wind the primary winding and achieve the designed voltage ratio by precisely controlling the number of turns of the winding. Next, when winding the secondary winding, attention should be paid to interlayer insulation treatment to prevent short circuits between windings. To ensure the quality of winding, it is necessary to strictly control the winding tension to avoid damaging the wire due to excessive tension or loosening the winding due to insufficient tension. After completing the winding, insulation testing will also be conducted on the winding to ensure that the electrical performance meets the standards, thereby enabling the EE10 transformer to achieve stable and efficient voltage conversion and other functions.

WhatsApp:13554723725/13380695029

We are a comprehensive research and development manufacturer specializing in the production of inductors, coils, audio isolation transformers, and power transformers. We have two factories and a team of engineers who can produce transformers according to your requirements and drawings. And quickly produce samples.

The winding of EE10 transformer starts with carefully selecting the appropriate winding wire diameter, which is determined based on the design requirements such as voltage and current of the transformer. When winding, professional winding equipment is usually used to tightly and evenly wrap the winding wire around the EE10 magnetic core skeleton. First, wind the primary winding and achieve the designed voltage ratio by precisely controlling the number of turns of the winding. Next, when winding the secondary winding, attention should be paid to interlayer insulation treatment to prevent short circuits between windings. To ensure the quality of winding, it is necessary to strictly control the winding tension to avoid damaging the wire due to excessive tension or loosening the winding due to insufficient tension. After completing the winding, insulation testing will also be conducted on the winding to ensure that the electrical performance meets the standards, thereby enabling the EE10 transformer to achieve stable and efficient voltage conversion and other functions.

EE10 Transformer

Transformer Manufacturing Process

EE10 Winding

-

ED8 Audio Transformer 600:600 1:1 SMD Shielded Audio Isolation Transformer 5H

Contact Now -

Flat EFD25 High Frequency Transformer Pulse Switching Power Supply Transformer

Contact Now -

T31*19*13 1.3mH Vertical Single Phase White Shell Filter Magnetic Ring Inductor with Compact Design

Contact Now -

Customized Magnetic Ring Inductor Copper Wire Ferrite Core Inductor Toroidal Coil

Contact Now -

High Power I-beam Inductor Dr Magnetic Core Inductor Leaded Inductor Wire Wound

Contact Now

Related Videos

EC42 Magnetic Electric Power Transformer Ferrite Core High Frequency Transformer

Other Videos

May 09, 2025

ZXY New Product - High Sound Quality Microphone Audio Transformer Component EI14

Other Videos

April 12, 2025

DR10X16 I-shaped High Current DIP Plug-in Power Inductor Customized Inductance

Other Videos

March 05, 2025

Lightweight EI19 1:4 Metal Dynamic Microphone Audio Transformer Permalloy

Other Videos

March 18, 2025

Customized Small High Quality MIC Transformer 1:8 Ribbon Dynamic Microphone Audio

Other Videos

March 22, 2025

Low loss 6.8UH 6R8 Chip Inductor SMD Shielded Power Inductor for DC/DC converter

Other Videos

March 21, 2025